Virtek Laserqc Manual

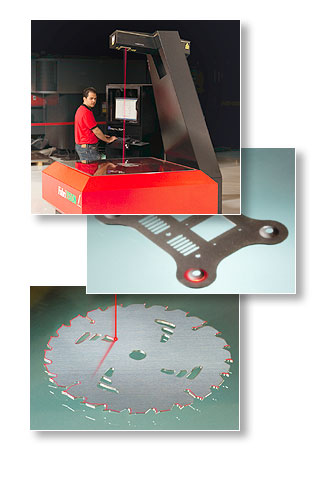

Scanning process captures the complete profile of existing parts or templates.

Virtek laserqc manual. Virtek laserqc is the first fully automatic and self calibrated laser inspection system of its kind. In addition quality control reports instill customer confidence. Virtek laserqc is a rapid inspection system that employs lasers to measure the accuracy and quality of two dimensional parts to tolerances within 0 05 mm 0 002 inches. Learn about the industries we serve throughout the globe.

Virtek iris 3d with the new vision positioning system vps significantly advances laser guided assembly with innovative flashalign functionality and superior laser line visibility plus a flexible workstation with multi tasking and a new thin client architecture. In addition quality control reports instill customer confidence. With laserqc this process is quick and easy. Service level agreements in addition to our service on demand options virtek offers a variety of customizable proactive service agreement options designed to maximize uptime and system performance.

Measures tolerances within 0 002 inches 0 05mm. Each part is inspected with more than 500 data points per second. Virtek trusted by the world s top tier aerospace and composite based manufacturers for best in class laser positioning solutions will showcase its newly enhanced all in one solution virtek iris 3d with vision positioning system vps and high visibility laser at camx 2019. Virtek vision international ulc is a market leader in laser projection and quality inspection systems improving productivity and reducing cost.

Virtek laser qc is a rapid inspection system that employs lasers to measure the accuracy of flat and formed parts as well as. Get to work right away. Laserqc enables quality control for 2d product layouts and quick first part inspection of products. 1 intuitive user interface allows inspection quickly and proficiently.

Virtek laserqc captures more than 500 data points per second and is accurate to within 0 05mm 0 002 inches. Virtek laserqc is designed for easy set up so it can be operational in only a few hours. Get to work right away. Virtek laserqc captures more than 500 data points per second and is accurate to within 0 05mm 0 002 inches.

Manual inspection and recording of the dimensions of 2d products is a time consuming process and one in which is it all too easy to make mistakes. The ease of operation. Virtek laserqc is designed for easy set up so it can be operational in only a few hours. The intuitive user interface allows new operators to.