Veeder Root Sensor Testing

Veeder root shall not be liable for errors contained herein or for incidental or consequential.

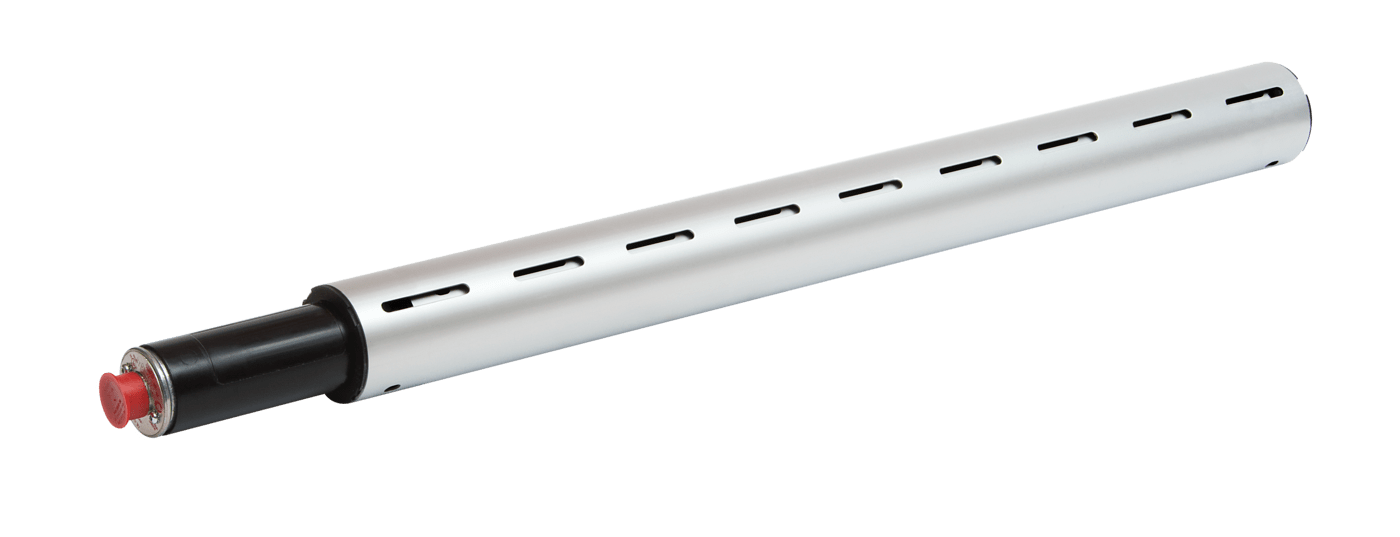

Veeder root sensor testing. Annual test needed alarm q t system failed to perform an annual test 0 1 gph. The piping sump sensor is installed in a containment sump and will detect the presence of a liquid. Detect dangerous hydrocarbon vapors in dry monitoring wells. Non discriminating piping sump sensor.

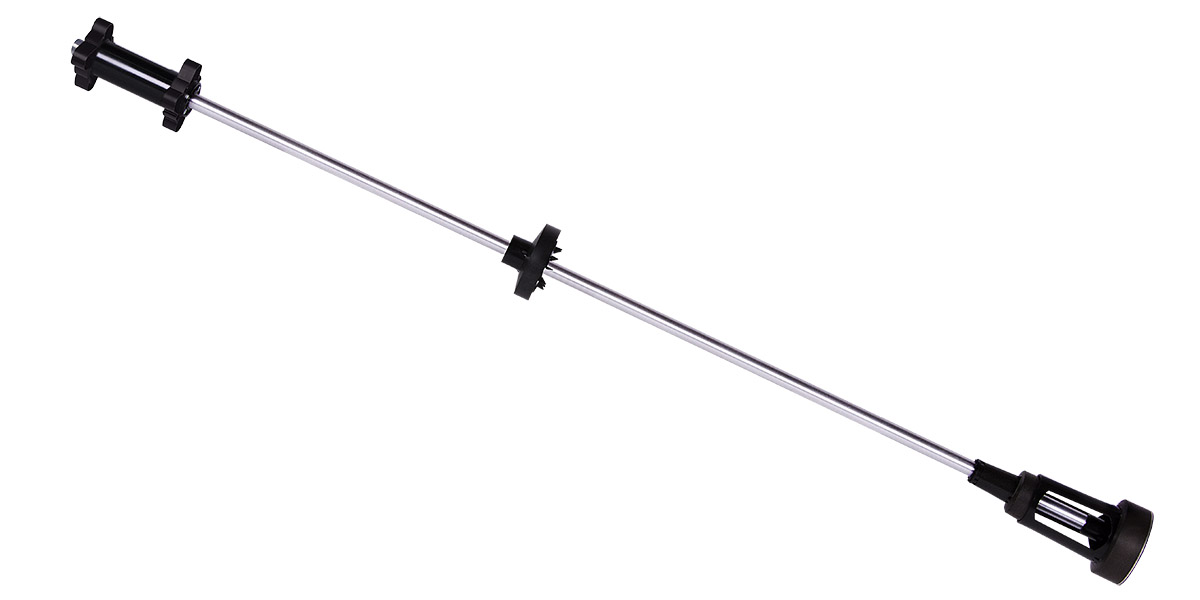

Periodic test fail alarm. Input or sensor number. Each vacuum sensor must have an associated liquid sensor which. The veeder root mag sump sensor uses proven magnetostrictive technology to detect hydrocarbons or water in sump spaces.

The proper test method for wrap around sensors according to veeder root protocol is to raise it up to grade examine the sensor to ensure it s not damaged and then place the sensor in a liquid. Dispensing halts if programmed to do so. Learn about using the veeder root tls 350 to do a 0 2 gph leak test by ben thomas of ust training. The mag sump sensor also allows for quick and easy periodic operability testing using the sump integrity testing feature if required by local agencies.

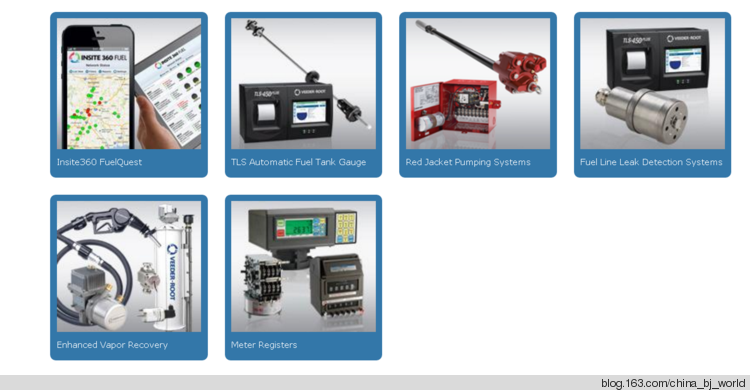

Periodic operability testing if required by local agencies. Veeder root certified technician training the veeder root technical training program strives to provide our network of service technicians the highest quality highly accessible training so that our mutual customers will receive the best installation start up and service for their veeder root and red jacket equipment. Hardware failure probe or interconnecting wiring to console. Get class a b and c ust operator training today at http.

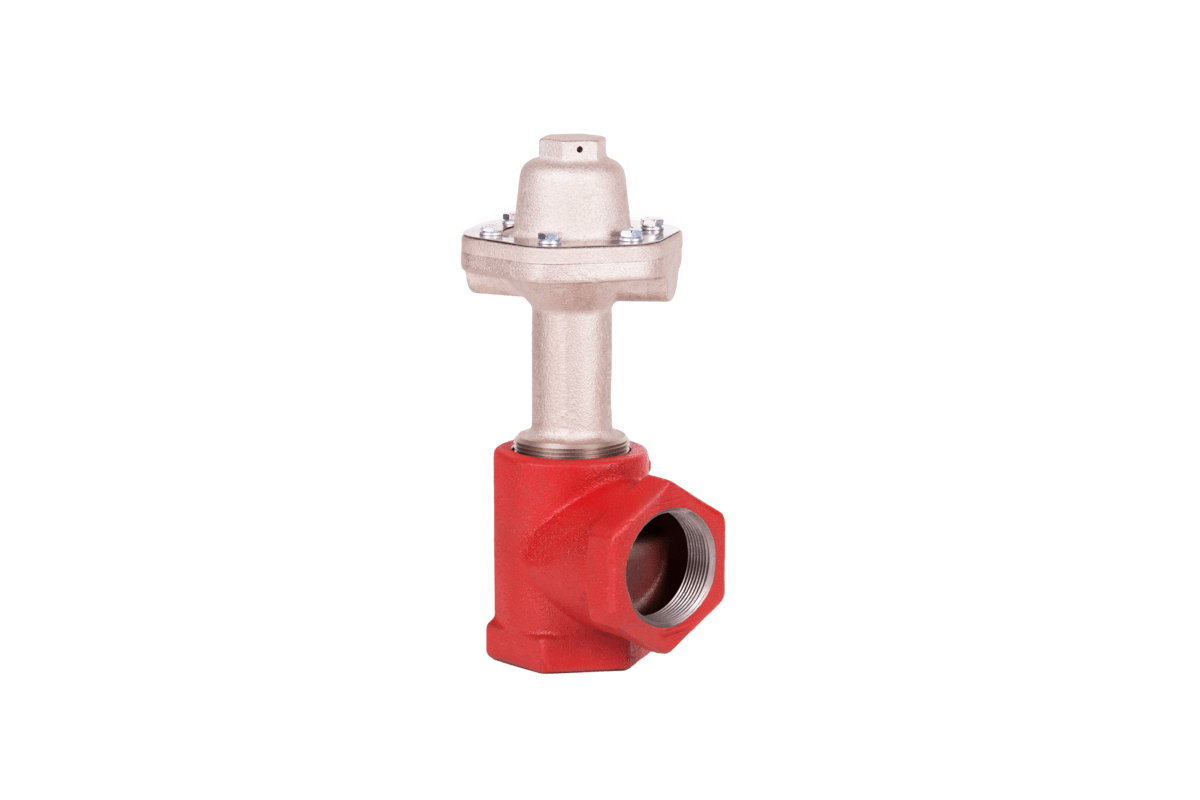

Where continuous monitoring of the sensor position is required by law site owners are. When vapors exceed a programmed threshold the vapor sensor sends an audible and visual signal to a veeder root automatic tank gauge console telling you where the problem is so you can act quickly to prevent serious safety and environmental hazards. Only tested while the pump is running. If an alarm state is indicated on the tank monitoring system display then the sensor passed the test.

0 2 test failure in fuel line or tank. Pressure sensor reading is less than 8 psi. System requirements satisfy regulations reduce exposure to risk leverage existing veeder root systems vacuum sensors connect to tank sump and piping interstices.