Ultrasonic Electrical Inspection

An ultraprobe detects high frequency sounds produced by these emissions and translates them via heterodyning down into the audible ranges.

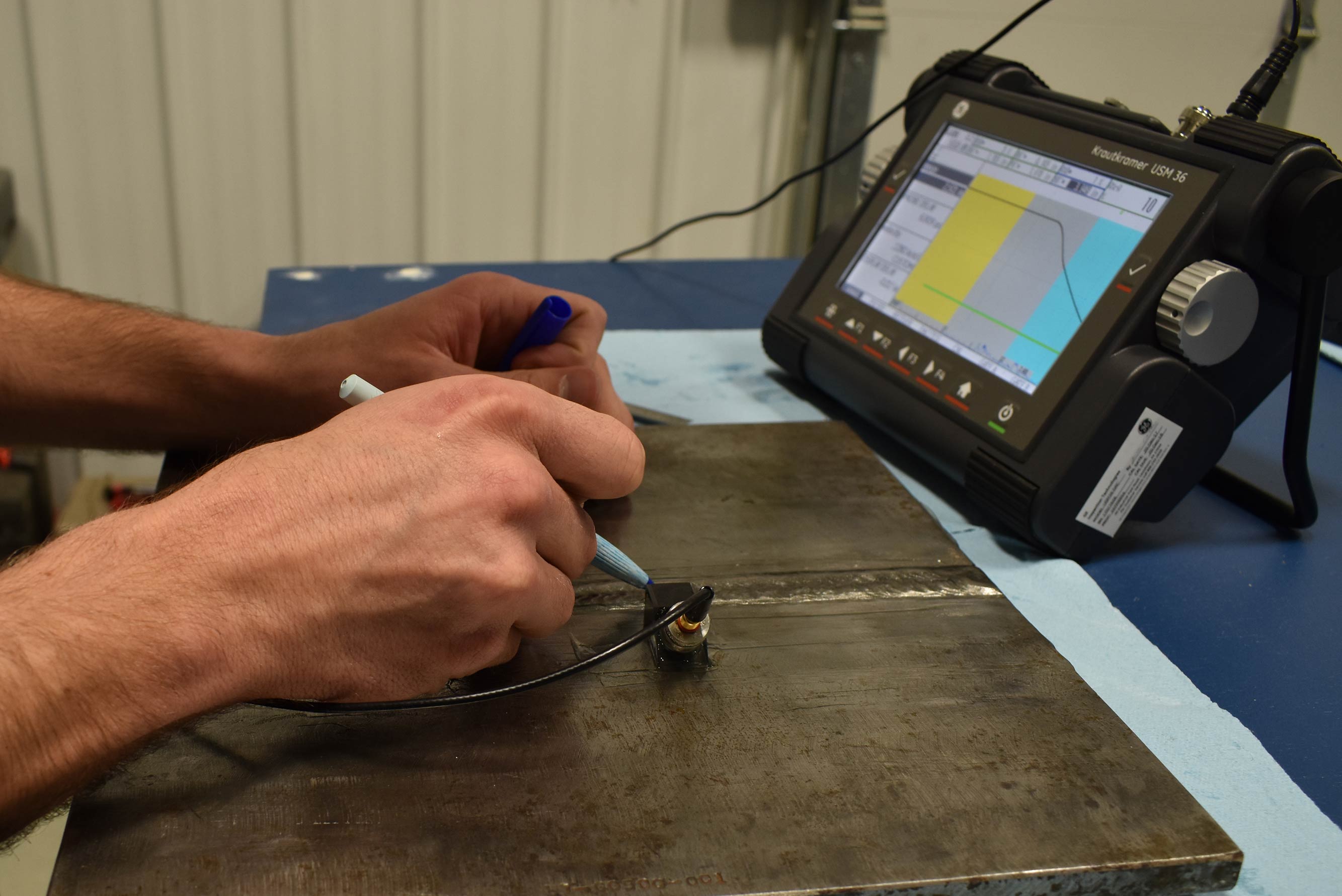

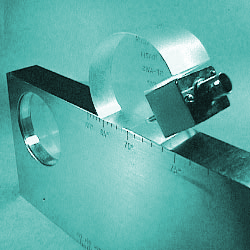

Ultrasonic electrical inspection. To illustrate the general inspection principle a typical pulse echo inspection configuration as illustrated below. However if background noise or other competing sounds are present raising or lowering the frequency 1 khz to 3 khz may limit the interference allowing the user to detect and. Ultrasonic electrical inspection white areas indicate voids in this ultrasonic image of a brazed contact tip switching contacts such as used in relays contactors and switchgear depend on brazed and welded joints between the contact tip typically silver alloy although other materials are also used and the carrier typically copper. Ultrasonic testing ut is a non destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested.

The inspection s findings an ultrasound examination of one of the units revealed a suspect sonic signature in the b phase coil. Corona can also occur at 1000 volts and greater. At any voltage thermal anomalies and sources of ultrasound such as tracking and arcing can occur. Ultrasonic inspection can be used for flaw detection evaluation dimensional measurements material characterization and more.

Ultrasonic testing ut is a family of non destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. When performing an ultrasonic electrical inspection the ultrasound technician may select 40 khz to detect an electrical anomaly sound waves moving through the air. Ultrasound and infrared technologies are a perfect match when conducting inspections of electrical equipment. For comparison an ultrasonic sound recording was taken of the sister unit which was under similar operating conditions.

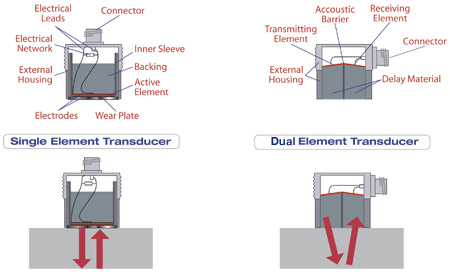

Gettle s ultrasonic testing specialists provide full service testing solutions that can identify electrical system issues before they lead to. In most common ut applications very short ultrasonic pulse waves with center frequencies ranging from 0 1 15 mhz and occasionally up to 50 mhz are transmitted into materials to detect internal flaws or to characterize materials. Ultrasonic testing ultrasonic testing uses ultrasound technology to detect high frequency sounds related to electrical discharges resulting from the ionization of arcing tracking and corona. How ultrasonic electrical inspection works partial discharge tracking arcing and corona all produce ionization which disturbs the surrounding air molecules.

In most common ut applications very short ultrasonic pulse waves with center frequencies ranging from 0 1 15 mhz and occasionally up to 50 mhz are transmitted into materials to detect internal flaws or to characterize materials.