Troubleshooting A Small Electric Motor That Fails

There are also other factors which greatly affect the performance of electric motors such as low resistance dirt moisture over current and vibrations.

Troubleshooting a small electric motor that fails. Here we provide an electric motor diagnostic table a troubleshooting guide that helps diagnose and repair most electric motor problems for motors found on hvac equipment in buildings such as air conditioners furnace or air handler blower fans oil burner motors well pumps and condensate return. A damaged or burnt out capacitor may hold only a fraction of the energy needed for the. The motor s design may be capacitor start or capacitor run. Troubleshooting a small electric motor that fails is most effective when you follow a step by step procedure that rules out potential causes and helps isolate defective circuits or components.

If leaks are found the motor must be replaced. Motor overloaded or jammed. Motor has been running then fails to start. These types of motors are what you will find in most home and workshop applications.

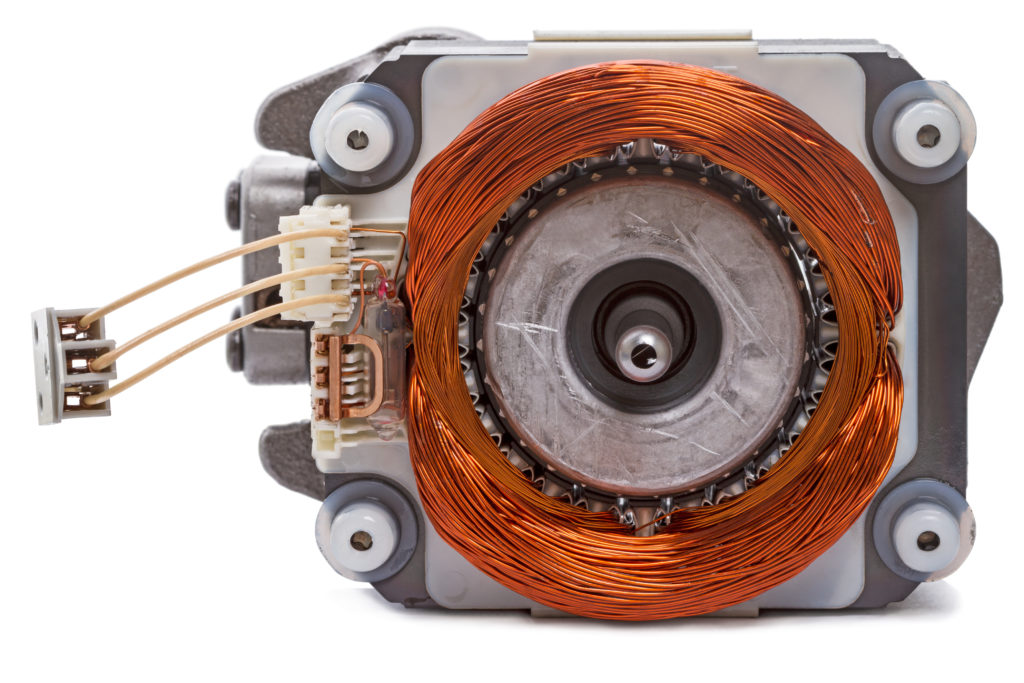

The most common cause of hvac failure during the hot summer is a motor capacitor. Stator is shorted or went to ground motor will make a humming noise and the circuit breaker or fuse will trip check for leaks through the coils. Electric motor starting run capacitor troubleshooting faqs questions answers about electric motor start boost or run capacitors capacitors are electric devices that get an electric motor running at start up or that help keep a motor running once it has started. A bad motor capacitor may cause starting problems or could shut off the motor while running.

Motor capacitors store electrical energy for the motor to use. This article describes a c electrical motor troubleshooting. Electric motors should be installed very carefully and should be looked after at regular intervals. As with all modifications on electric or electronic equipment make sure that you unplug the motor before making any modifications or repairs.

If the capacitor has failed the symptom is that the motor won t start. A quick check out can be done with a simple ohm meter but there s a lot more information to collect and weigh before actually putting it to use. Most of the electric motor failures occur at the start up. When a motor fails it is often difficult to see why it failed just by looking at it.

Special purpose industrial motors dc three phase will have some differences and i still know nothing about them. Fuse or circuit breaker is tripped replace the fuse or reset the breaker. Electric motor test repair guide. The higher the capacitance of the capacitor the more energy it can store.

Hatfield vp of engineering and repair at heco all systems go goes over common types and causes of failures in electric motors at the 2016 reliabi.