Steam Equipment Sample Cooler

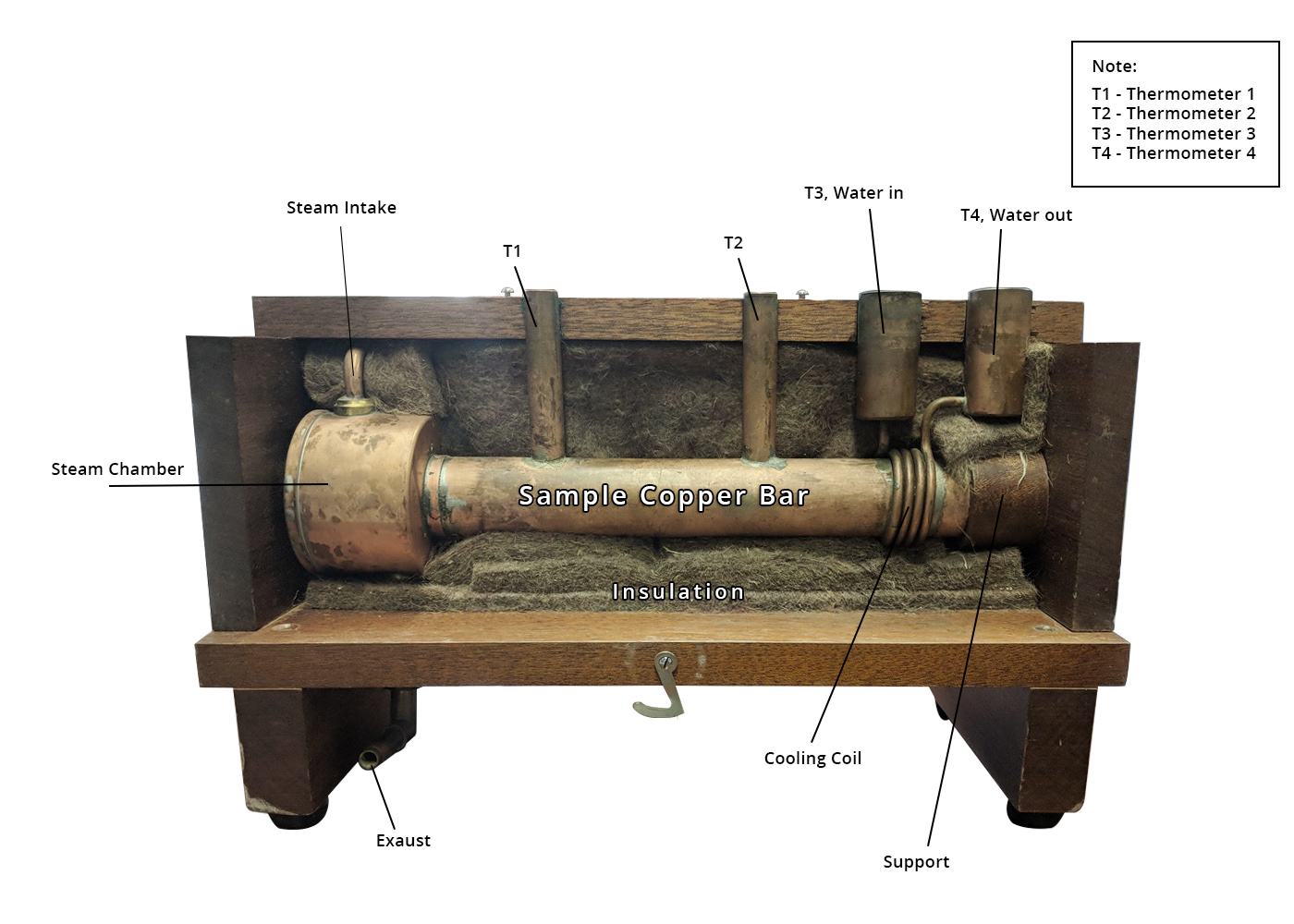

Cooling water inlet temperature quality 5.

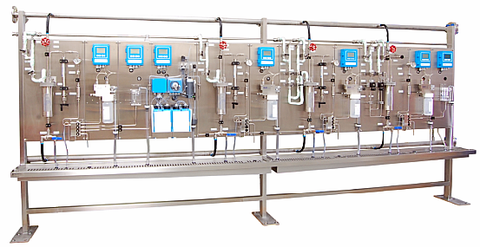

Steam equipment sample cooler. Insufficient cooling water flow will result in rapid cooler failure. Buy steam boiler sample cooler from brands like neptune at cannon water technology. The refinery sample coolers are shell type coolers designed for process pipe and flange connection. Mfg marketed by steam equipments pvt ltd no 44 tiny industrial estate kondhwa budurk pune 411 048.

Typical custom design with bigger diameter spiral wounded coil and open shell heat exchanger. Setup sample coolers with isolation valves so they can be drained and to provide pressure relief on the shell side of the cooler in the event of a loss of cooling water incident. Sample flow required 6. For instance steam sample coolers can provide condensate.

Sample inlet pressure 3. Sample coolers are used to cool fluids or vapors to a point they can be safely handled for collection and analysis. Sentry equipment world headquarters. The company delivers design development manufacture supply and after sales service of gas and liquid analytical systems steam and water analysis system swas and sample coolers used in refiniries power plants and process industries.

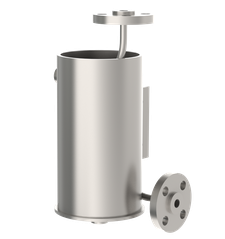

Because of this the sample cooler size will be determined by your samples required flow rate and the steam inlet pressure. Sample outlet temperature required. Oconomowoc wi 53066 1 262 567 7256 sentry equipment houston process monitoring tech center. The 316l sample coolers are shell and spiral tube heat exchangers designed specifically to condense and cool pure steam wfi or usp pw via mains or chilled water.

Boiler water sample coolers are a safe method to cool down water samples. The sample to be cooled high flows through the tube side of the cooler and the cooling fluid flows through the shell side. Sample inlet temperature 2. The sample is precision metered by an upstream sample metering valve and flows down through the spiral sample tube for safe sterile extraction of room temp samples at the bottom of.

For steam samples flow rates are lower due to the high velocity of the steam as it flows to the sample panel. With information found on the sample cooler inquiry questionnaire a sample cooler can be provided for applications such as steam boiler water chemical processes and others in high pressure and high temperature ranges. 966 blue ribbon circle north. Samples should be routed with tubing cooling water with piping typically.

Data required for selection of sample cooler.